$1,099.00 Original price was: $1,099.00.$999.00Current price is: $999.00. inc GST

Cast steel anvil in 6150 carbon steel, good for knife makers wanting to forge their own blades.

These are a taller and thinner model than the standard stocky anvils, in a better steel alloy that hardens deeper.

Nordic Edge is super proud of our own take on the classic London Pattern Anvil, with a nod to BK anvils that used to be made right here in NSW. This is our own anvil custom made for Nordic Edge.

**Pick up from Midvale, WA only**

6

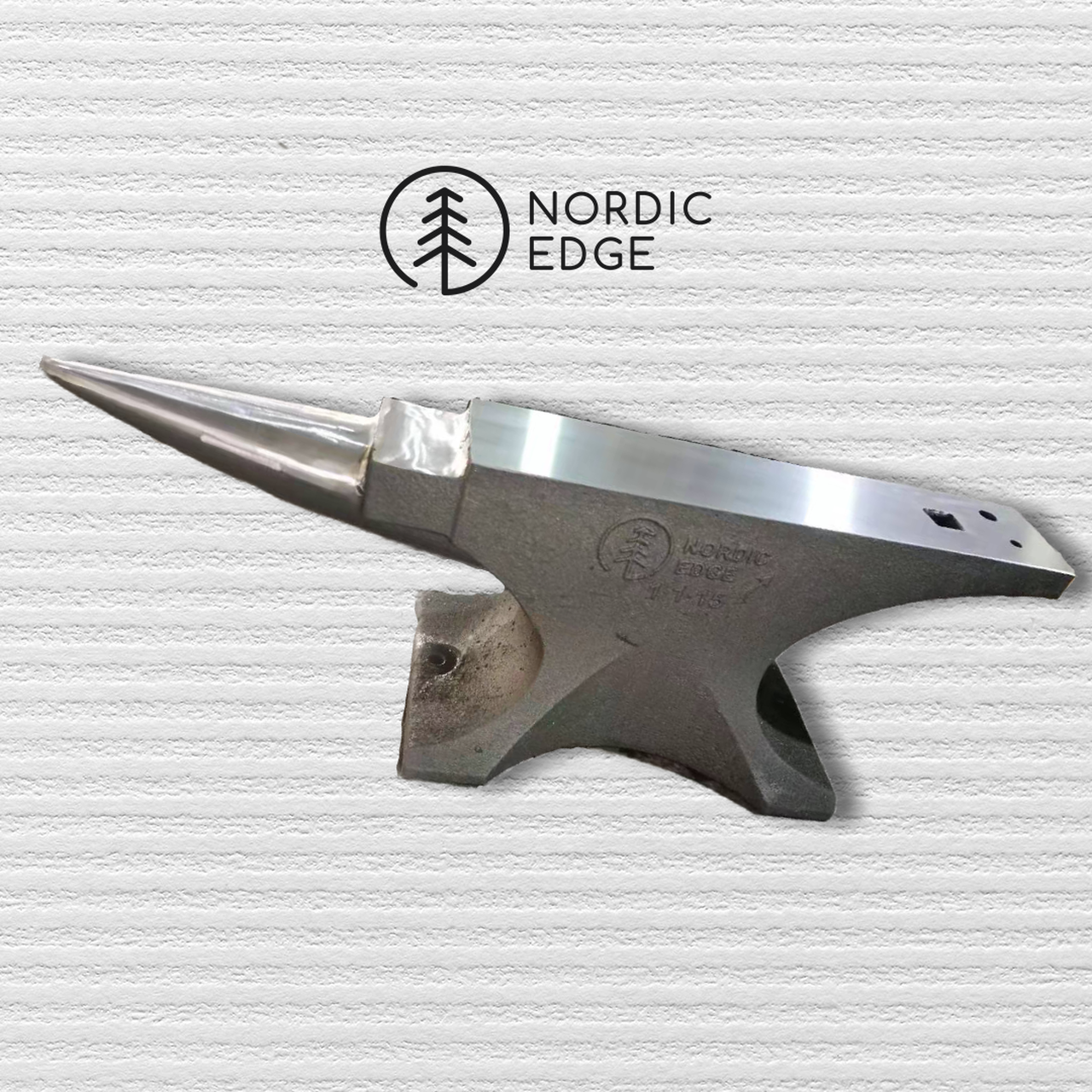

70 KG Cast Steel Blacksmith Anvil -The Troy

**This is our premium model anvil in 6150 steel and a more elegant shape **

Cast steel anvil in 6150 carbon steel, good for knife makers wanting to forge their own blades.

These are a taller and thinner model than the standard stocky anvils, in a better steel alloy that hardens deeper.

Nordic Edge is super proud of our own take on the classic London Pattern Anvil, with a nod to BK anvils that used to be made right here in NSW. This is our own anvil custom made for Nordic Edge.

The anvil design is by Troy Hageman of Nowra knives and we call this 70 kg model the “Troy”;

- Anvil face is 460 x 93 mm

- Cast 6150 steel hardened face to 57 HRC

- long, stable base at 350 x 197 mm

- Hardy hole is 25.4 x 25.4 mm (1″)

- Pritchel holes are 10 mm and 15 mm

- Cutting face on horn side is 90 x 74 mm

- Upsetting block on far side of anvil is 185 mm long

- Long, rounded horn thins to 12 mm tip (1/2″)

- Anvil height 241 mm, footprint 350 x 200 mm

6150 Steel: Premium anvil steel

There is nothing wrong with our standard anvils in 1050 shallow hardening steel. We use them ourselves, they are a good beginner anvil.But 6150 is a step up, this is a much tougher steel and hardens deeper down from the face of the anvil.

6150 is a medium-carbon spring steel not unlike 5160 but with added manganese and chromium, tough enough to be used for knife blades and even machined parts like gears. As a testament to it’s choice for premium anvils is that Master Blacksmith Uri Hofi cast his brand of Hofi Anvils – as well as his famous Hofi Ergonomic Hammers – in 6150 steel with Angele in Germany.

6150 has a typical chemistry of Carbon 0.50%, Manganese 0.80%, Silicon 0.30%, Chromium 1.00%, Vanadium 0.15%. The main features making 6150 so attractive for anvils is not high HRC but toughness, wearability and the ability to harden deeper than for instance 1050 steel.

Design:

- The shape is tall and thin providing the double benefit of having more of the weight under the hammer, as well as letting the blacksmith stand closer to the work than a stockier, wider anvil face.

- The anvil also has an upsetting block on the far side of the anvil, down on the base. This allows for stock being upset to be based lower than the anvil face for more power.

- This is our version of a classic London Pattern anvil, with rounded lines holes on the short sides of the base for bolting down.

Dressing the anvil face:

Dressing the anvil is done by rounding the edges using a flap wheel on an angle grinder, or hand files. And the round horn ground nice and even to remove cast marks and the black paint. This dressing makes the anvil more useful, as forging with the sharp corners tend to pinch the steel and create cracks.

These are cast from premium 6150 steel and should with minimal care be the last anvil you ever buy.

**Pick up from Midvale, WA only**

Limited Stocks, please call to place an order!

Related products

CLEARANCE PRODUCTS

CLEARANCE – Bowie Dive Knive with Locking Sheath & Serrated Back